Centennial Hall – Materials And Technology

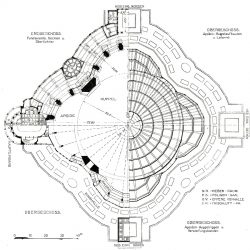

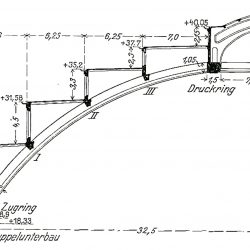

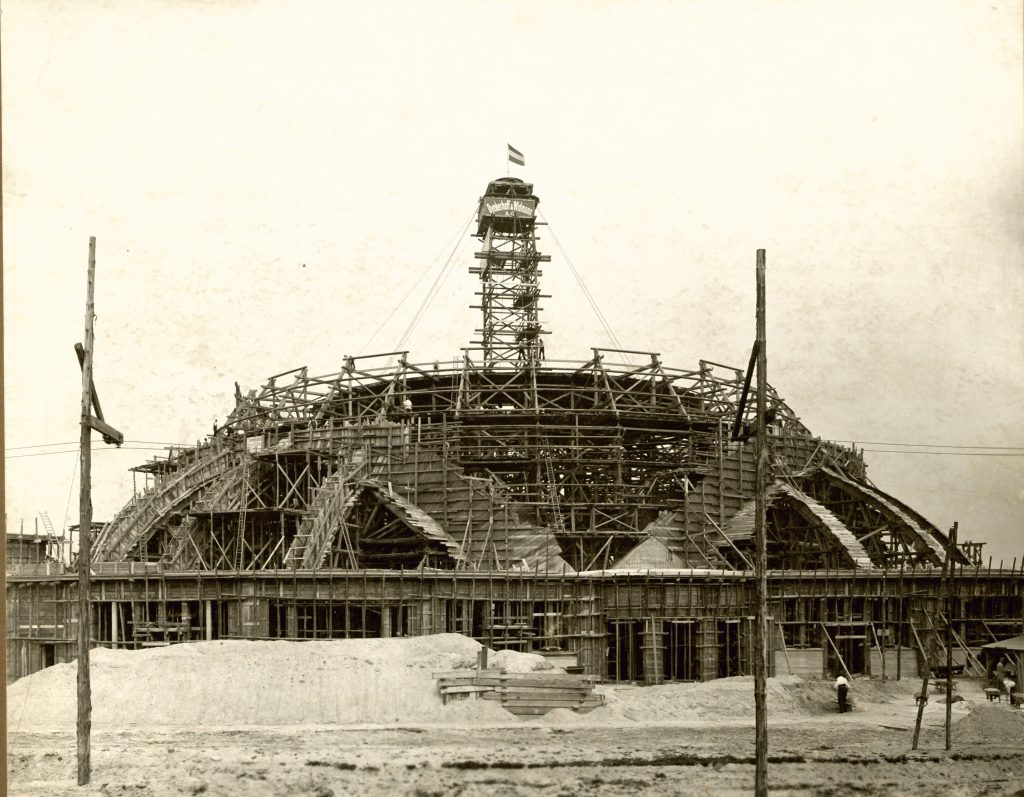

The initial works on the Centennial Hall (which involved construction site preparation) started in May 1911. In August and September, the principal construction axes were identified and earthwork commenced. By January 1912, the foundations were laid. In April, the work on scaffoldings and formworks for the Hall’s four main pillars started, and by September, the stage of covering the dome with concrete was successfully completed, and formation of window frames and stepped tiers of walls and floors commenced. In December 1912, Dyckerhoff & Widmann presented the concrete shell to the City.

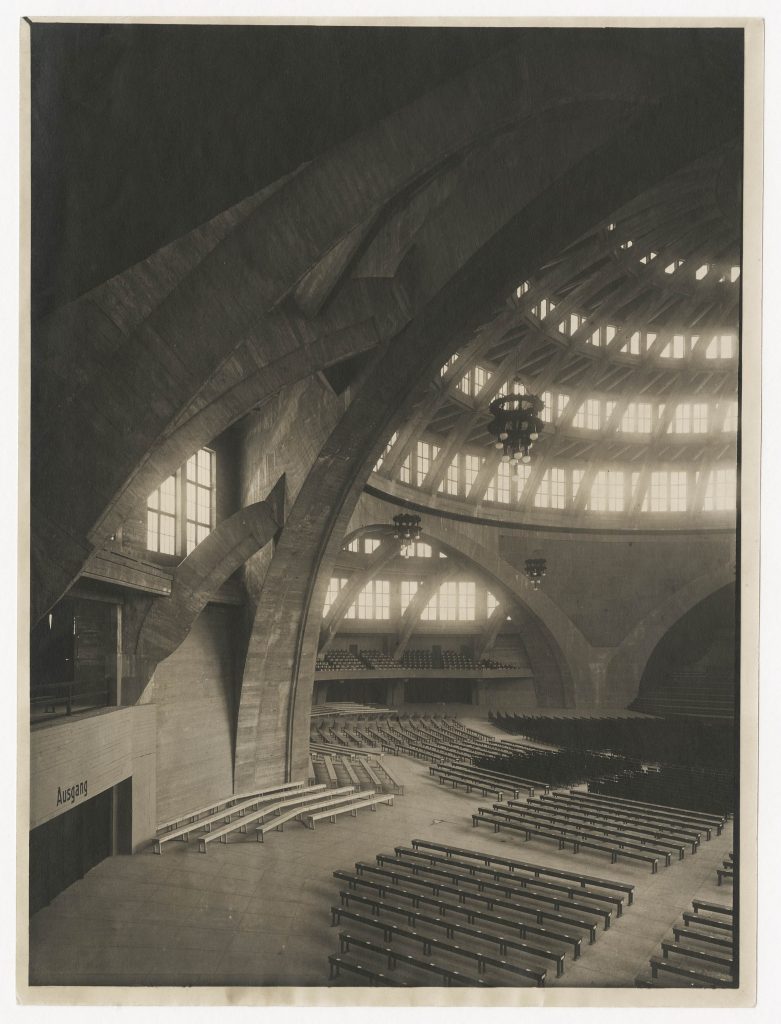

Reinforced concrete – a light and flexible material, despite its excellent technical parameters, raised doubts among Berg’s contemporaries. Steel had its value – measured by its weight. Despite their huge load and significant costs, the steel structures had confidence of its constructors. The moment of the dismantling of the scaffolding, which would leave the hall without any additional support, was anxiously awaited. The fear of the workers responsible for the construction turned into astonishment when Berg went out and asked a passer-by to help him remove the first formwork offering the man one gold mark for his assistance. At that moment reinforced concrete initiated its era of triumph in construction and architecture.

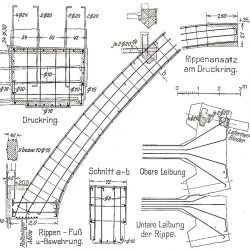

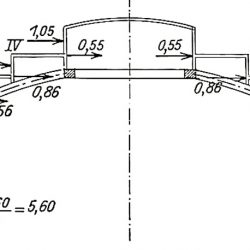

The top quality materials were used for the Centennial Hall’s construction. Special cement, supplied by the Silesia Cement Plant in Opole and tested under restrictive conditions, was used to make concrete. Based on the results of steel resistance tests, high-grade rolled steel was selected. In the sections exposed to large stress, the highest quality Strzegom granite was used, i.e. an aggregate characterized by top parameters. Windows were made of iron wood imported from Australia.

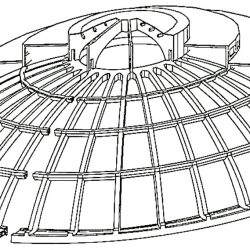

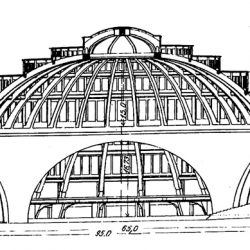

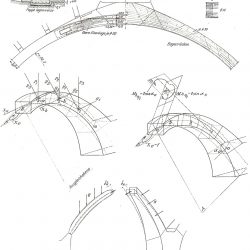

At the time of its construction completion, the Centennial Hall’s dome with the span of 65 meters was the largest structure of this type in the world, and it even outshone the Roman Pantheon. Reinforced concrete construction was also significantly lighter and more resistant. In order to highlight „truth of the material” used for construction of the Hall, Berg decided to reject decorations and ornaments.

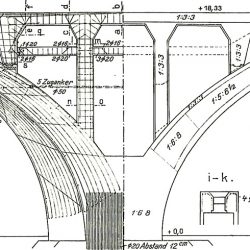

Unique contruction technology

Centennial Hall was erected in just 14 months. Two towers moving along tracks encircling the building enabled to work very fast. Connected by means of ropes with the top of the building constructed, electrically powered towers formed a carousel cable raising above the scaffolding, capable of carrying loads up to 2500 kg.